Product classification

Contact Us

If you have the intention to cooperate, please contact us immediately and we will give you feedback as soon as possible!

Composite Anti-Drainage Board

Composite anti-drainage board is a new type of geosynthetic material derived from non-woven geotextile and plastic anti-drainage board.

Classification:

Anti-seepage Drainage Material Series

- Description

-

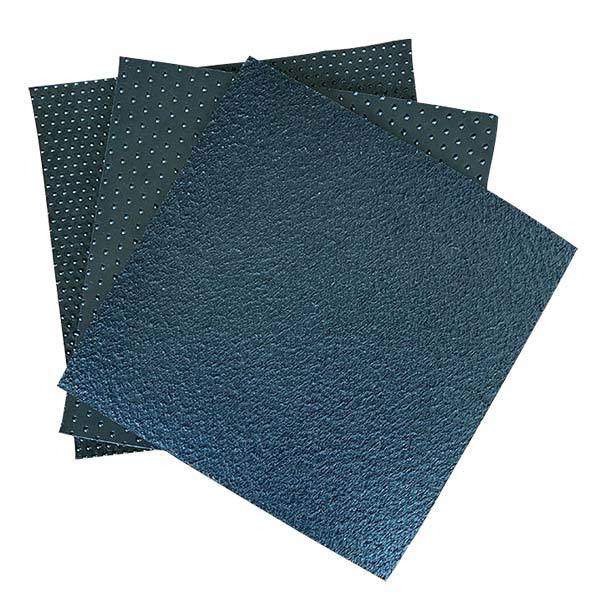

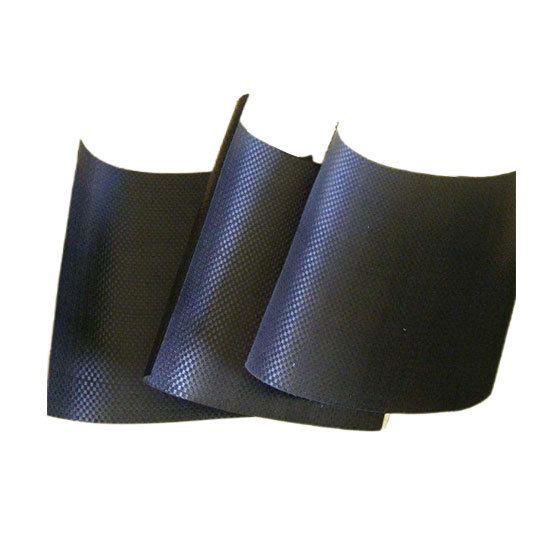

- Commodity name: Composite Anti-Drainage Board

Composite anti-drainage board is a new type of geosynthetic material derived from non-woven geotextile and plastic anti-drainage board.

Product Overview

Composite anti-drainage board is a new type of geosynthetic material derived from non-woven geotextile and plastic anti-drainage board. Plastic anti-drainage board using high-density polyethylene (HDPE) as the main raw material, plastic base plate after stamping made of conical protrusion or stiffening rib bumps (or hollow cylindrical porous), conical protrusion of the top surface of the glued or composite layer of filtration geotextile through thermal bonding process, thus forming a composite anti-drainage board. The product has high compressive strength, good flexibility, high tensile strength, corrosion resistance, aging resistance, resistance to plant puncture, will not decompose, waterproof environmental protection and other characteristics, more suitable for use in the actual construction, easy to press and install. Currently widely used in: landfills at home and abroad, highways, railroads, airports, power plants, yards, ports, reclamation, sewage treatment plants, land reclamation, water conservancy and hydropower, dock construction and other projects in the soft foundation treatment project.

The application of composite anti-drainage board in landfill is mainly to replace cobbles or gravel as air and water conductive layer with obvious effect.

Comparison of the advantages and disadvantages of composite anti-drainage boards and traditional gravel as a conductive drainage layer

(i) Conventional lithotripsy systems

In the landfill closure project, it is often used to lay 30-50cm high cobbles or gravel under the impermeable layer as the air-conducting layer; and 30-50cm high cobbles or gravel on the impermeable layer as the drainage layer.

Advantages: natural materials, excellent conductivity and drainage performance.

Disadvantages:

1, cobblestone construction process will cause some unavoidable damage to the impermeable layer, causing potential safety hazards to the quality of the project.

2, cobblestone as a guide layer, its own weight, space occupancy, so that the impermeable layer produces a certain load, the later will cause a certain ground subsidence.

3, cobblestone cost is high, construction difficulty, high labor cost. And need to face the procurement difficulties.

4, the use of cobblestone as a drainage layer, need to cooperate with the use of geomaterial filtration layer, disguised as an increase in cost.

5, the production process of gravel need to destroy the mountain, will have a certain impact on the natural environment, not in line with the concept of environmental protection.

(ii) Composite anti-drainage board drainage system

In the landfill closure project, composite anti-drainage board is utilized to replace the gravel air-conducting layer under the impermeable layer and the gravel water-conducting layer on the impermeable layer.

Disadvantages: drainage performance is slightly inferior to cobbles, need to assist a layer of composite drainage network to achieve optimal drainage effect.

Advantages:

1, low cost investment, low transportation cost, easy and fast construction, fast construction period.

Every 3 to 5 people can lay a group of composite anti-drainage board materials, multiple work surfaces at the same time construction, greatly reducing the construction period.

2, to ensure that the impermeable layer will not be damaged by external forces.

Composite anti-drainage board so that the construction can be laid only by manpower, without mechanical push, thus avoiding the destruction of the impermeable layer during construction. And the load on the earth is small, reducing the destruction of the seepage control layer in the later stage.

3, root-blocking waterproofing, double-layer protection, auxiliary seepage control.

Composite anti-drainage board in the role of excellent drainage guide, at the same time, the template of the drainage board will play a good role in waterproofing, double layer of seepage control, greatly increasing the safety and quality of the project.

At the same time, the composite anti-drainage board will prevent the surface layer of green plant roots downward extension, to avoid the destruction of plant roots on the impermeable layer.

4, adapt to the subsidence of the terrain, does not affect the effect of drainage guide.

As a geosynthetic material, its excellent flexibility, tensile strength, will adapt to the subsidence of the terrain over the years, and will not affect its own drainage performance.

5, safety and environmental protection, long service life.

The product has high compressive strength, good flexibility, high tensile strength, corrosion resistance, aging resistance, plant puncture resistance, will not decompose, waterproof and environmental protection characteristics. Will not cause pollution of groundwater, its good chemical inertia to ensure its long service life.

Composite anti-drainage board performance indicators are as follows

Serial No.

Project Name

HDPE

HDPE

HDPE

HDPE

HDPE

1

Unit Mass,≥g/㎡

800

1000

1000

1000

2000

2

HDPE average film thickness,≥mm

0.8

1.0

1.0

1.0

——

3

Plate thickness,≥mm

12

12

16

20

20

4

Tensile Strength,≥N/5cm

350

450

450

450

——

5

Compressive load,≥KPa

300

300

300

300

350

6

Tensile Elongation,≥%

30

40

40

40

——

7

Puncture Strength,≥N

350

400

400

400

——

8

Vertical water throughput,≥cm3/cm.s

7.20

7.20

10

12.5

21.5

Key words:

HAO YANG

More products