Product classification

Contact Us

If you have the intention to cooperate, please contact us immediately and we will give you feedback as soon as possible!

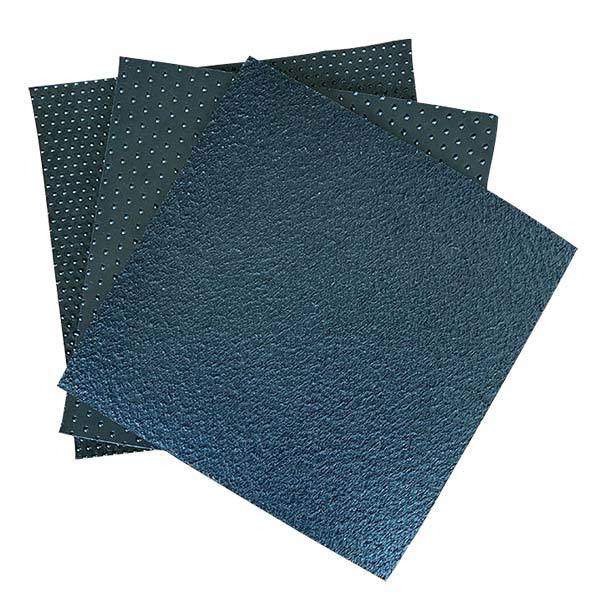

Rough Surface Geomembrane

Tensile, tear resistance, top breaking and other physical and mechanical properties of the index is high, the product has high strength, better extension properties, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, seepage control performance is good.

Classification:

Geomembrane Series

- Description

-

- Commodity name: Rough Surface Geomembrane

Tensile, tear resistance, top breaking and other physical and mechanical properties of the index is high, the product has high strength, better extension properties, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, seepage control performance is good.

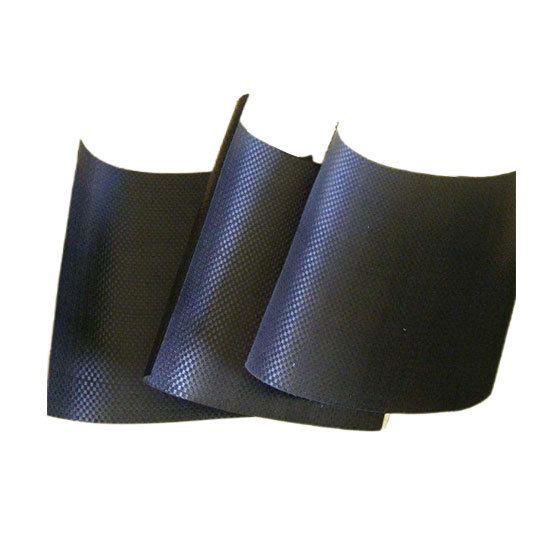

Rough Surface Geomembrane

Rough HDPE geomembrane is a new type of seepage control material, single roughness, double roughness and other HDPE geomembrane to increase the coefficient of friction, anti-slip function, more suitable for steep slopes and vertical seepage control, to improve the stability of the project.HDPE geomembrane has excellent temperature adaptability, weldability, weather resistance and good aging resistance, chemical corrosion resistance, resistance to environmental stress cracking performance and resistance to poking through performance. Therefore, it is especially suitable for underground engineering, mining engineering, landfill, sewage or waste residue treatment site as anti-seepage material.

Product Performance

Tensile, tear resistance, top breaking and other physical and mechanical properties of the index is high, the product has high strength, better extension properties, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, seepage control performance is good. Can meet the water conservancy, municipal, construction, transportation, subway, tunnel, engineering construction of seepage control, isolation, reinforcement, crack prevention and reinforcement of civil engineering needs. Commonly used in embankment dams, drainage ditches seepage control treatment, as well as anti-pollution treatment of waste sites.

Product Use

1, landfill, sewage or slag treatment seepage control.

2, river embankment, lake dam, tailings dam, sewage dam and reservoir, channel, liquid storage pond (pit, mine).

3, subway, basement and tunnel, tunnel seepage control lining.

4, roadbed and other foundation salt seepage control.

5, embankment, dam front horizontal seepage control cover, foundation vertical seepage control layer, construction cofferdam, waste yard.

6 seawater, freshwater farms.

7, roads, highways, railroads, foundations, expansion of soil and waterproof layer of humid loess.

8, Roof seepage control.

Product Specification

Thickness: 1.0-3.0mm

Width: 7m

Main performance and technical indicators

Technical Performance Indicators of HDPE Shih Wang Sense of Garbage Pei Li Field Width (CJ-T234-2006) Serial No. Value Measured Value 1.00mm 1.25mm 1.50mm 2.00mm 2.50mm 3.00mm 1 Height of Gross Finish/mm 0.25 2 Least density(g/cm2) 0.939 3 Tensile properties Yield strength (stress) (N/mm) 15 18 22 29 37 44 Rupture strength (stress) (N/mm) 10 13 16 21 26 32 Yield elongation/% 12 Elongation at break/% 100 4 Right angle tear strength/N 125 156 187 249 311 374 5 Puncture strength/N 267 333 400 534 667 800 6 Mine environmental stress cracking (single point

Notched Fear Load Tensile Method)/h300 7 Soot Carbon black content (range) / % 2.0~3.0 Carbon black dispersion 9 out of 10 observation areas should be in level 1 or 2, and no more than 1 should be in level 3 8 Oxidation Induction Time (OIT) Standardized OIT/min 100 Oppressive OIT/min 400 9 85°C oven aging (minimum average) Retention/% of standard OIT after 90 d of baking 55 Retention/% of high-pressure OIT after 90 d of baking 80 10 UV strength Retention/% of standard OIT after 1600h of external irradiation with vectors 50 Retention/% of high-pressure OIT after 1600h of UV galling 50 11 -70℃ low-temperature impact performance Pass 12 Water vapor permeability coefficient g-cm/(cm2-s-Pa) ≤1.0×10(-13) 13 Dimensional stability/% ±2

Key words:

HAO YANG

More products