Product classification

Contact Us

If you have the intention to cooperate, please contact us immediately and we will give you feedback as soon as possible!

Bentonite Waterproofing Blanket

Bentonite mineralogical name for montmorillonite, natural bentonite according to the chemical composition is mainly divided into sodium-based and calcium-based two categories.

Classification:

Waterproof Blanket Series

- Description

-

- Commodity name: Bentonite Waterproofing Blanket

Bentonite mineralogical name for montmorillonite, natural bentonite according to the chemical composition is mainly divided into sodium-based and calcium-based two categories.

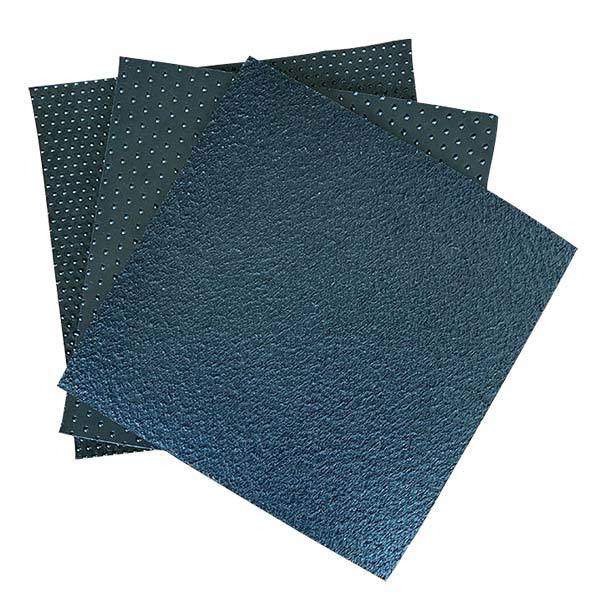

Bentonite waterproofing blanket (GCL): bentonite waterproofing blanket also known as bentonite waterproofing mat, bentonite composite waterproofing mat (English name: GCL), bentonite waterproofing blanket consists of three layers, the upper and lower layers were geotextile fabrics, mainly for the role of protection and reinforcement, so that it has a certain degree of overall puncture resistance and tensile strength; the middle of the sodium bentonite granular layer, which is processed by the natural clay mineral material. Has a high expansion and high water absorption capacity, low permeability when wet, mainly for seepage control. Bentonite waterproofing blanket using a special needle punching method, special needle punching process is to make the coarse fiber from the upper geotextile through the bentonite layer, fixed in the lower geotextile, the three parts of the combination as one, effectively enhancing the integrity of the bentonite waterproofing blanket, bentonite waterproofing blanket shear strength and tensile strength is greatly enhanced, which makes the composite waterproofing bentonite mat can be used individually, but also can be used in combination with the compacted clay seepage control body or geomembrane. Body or geomembrane combined use. Mainly used in environmental engineering in the waste landfill, landscape artificial lakes, subway tunnels, underground infrastructure construction and other projects to solve the sealing, isolation, anti-seepage problems, waterproofing effect is good, strong resistance to damage.

Bentonite waterproofing blanket principle

Bentonite mineralogical name for montmorillonite, natural bentonite according to the chemical composition is mainly divided into sodium-based and calcium-based two categories. Bentonite has the property of expansion in contact with water, generally calcium-based bentonite expansion, its expansion is only about 3 times its own volume; and sodium-based bentonite expansion, about l5 times its own volume or so, can absorb 6 times its own weight of water, so that the expansion of the bentonite formed by the high-density colloid with the performance of the exclusion of water. The use of this performance, people use sodium bentonite to do waterproof materials. In order to facilitate construction and transportation, bentonite locked in the middle of the two layers of geosynthetics, play a protective and reinforcing role, so that the GCL bentonite waterproofing blanket has a certain degree of overall tensile and puncture strength.

1. Compactness: sodium bentonite in the state of water pressure to form a high-density diaphragm, the thickness of about 3mm, it is permeable to α × 10 -11 m/sec below, equivalent to 100 times the thickness of 30cm clay compactness, has a strong self-preservation of water performance.

2. assured waterproof performance: because sodium bentonite is a natural inorganic material, even after a long time or changes in the surrounding environment, will not occur aging or corrosion phenomenon, so waterproof performance is long-lasting.

3. Construction is simple, short construction period: compared with other waterproof materials, construction is relatively simple, do not need to heat and paste. Only need to use bentonite powder and nails, washers, etc. for connection and fixing. Construction does not require special inspection, if found waterproofing defects are also easy to repair. gcl is the existing waterproofing materials in the shortest construction period.

4. Unaffected by temperature: it will not be brittle even in cold climate conditions.

5. waterproof material and the integration of the object: sodium bentonite and water reaction, with 13-16 times the expansion capacity, even if the concrete structure vibration and settlement, GCL within the bentonite can repair the cracks in the concrete surface within 2mm.

6. Green: bentonite is a natural inorganic material, harmless and non-toxic to humans, no special impact on the environment, has a good environmental protection.

Bentonite waterproofing blanket use

1. Landfill impermeable closure treatment project

2. Water feature and artificial landscape project

3. Underground oil storage tank seepage control project

4. Reservoir (pool) seepage control project

5. Channel and canal seepage control project

6. Subway project

7. Tunnel project

8. Waterproofing of underground structures and underground foundations, etc.

Bentonite waterproofing blanket application

1. For new industrial and civil roof planting gardens, basements, roofing and other waterproofing projects;.

2 subway, railroad, municipal highway, light industry, petroleum and metallurgy and other industries of various waterproofing projects.

3. seepage control project for earth and stone repair and reinforcement.

4. desert management, environmental transformation, landfill, artificial lake, artificial landscape and other large areas of soil waterproofing cover; 5. in water conservancy projects, waterproofing projects, waterproofing projects, waterproofing projects, waterproofing projects, waterproofing projects

5. in the water conservancy project performance is more excellent, in the water storage buildings, small reservoirs, reservoir dams, irrigation channels, ponds, fish ponds and other large-scale seepage control construction can be widely used.

The main performance and technical index of the product

Bentonite waterproofing blanket (GCL) is a new type of geosynthetic material. It consists of graded natural sodium bentonite particles and the corresponding additives mixed uniformly, by special technology and equipment, the bentonite particles fixed between the two layers of geotextile, made of bentonite waterproofing blanket, not only has all the characteristics of geosynthetics, but also has excellent waterproofing (seepage) performance. Its waterproofing mechanism is: bentonite particles in contact with water expansion, so that the formation of a uniform colloidal system, in the two layers of geotextile restriction, so that bentonite from the disorder into an orderly expansion, the result of continuous expansion of water-absorbing results is the bentonite layer to achieve its own dense, thus waterproofing effect.

-- has excellent waterproof seepage performance, impermeable hydrostatic pressure up to 1.0MPa or more, permeability coefficient 10 -2 cm/s

-- Bentonite is a natural inorganic material, will not occur aging reaction, good durability; will not cause any adverse impact on the environment, is an environmentally friendly material!

-- With all the characteristics of geotextile materials, such as separation, reinforcement, protection, filtration, etc.

-- construction is simple and not subject to construction environment temperature restrictions, 0 ℃ can also be constructed. Simply lay the GCL blanket flat on the ground.

-- Easy to repair; even after waterproofing (seepage) is completed, if the waterproofing layer is accidentally damaged, a simple repair of the damaged area will restore perfect waterproofing performance.

-- High performance-price ratio, very wide range of applications.

-- The width of the product can be up to 6 meters, matching the international geotextile (membrane) specifications, greatly improving the construction efficiency.

Serial No. Item GCL-NP Technical Specification GCL-OF Technical Specification GCL-AH Technical Specification 1 Bentonite waterproofing blanket mass per unit area(g/m2) ≥204000 and not less than the specified value ≥ 24000 and not less than the specified value ≥ 24000 and not less than the specified value 2 Bentonite expansion index(mL/2g) ≥24 ≥24 ≥24 3 Amount of blue absorption{g/100g) ≥30 ≥30 ≥30 4 Tensile Strengths(N/100mm) ≥600 ≥700 ≥600 5 Elongation Under Maximum Load(%) ≥10 ≥10 ≥8 6 Peel Strength(N/100mm)Nonwovens and Woven Fabrics ≥40 ≥40 - 7 Peel Strength(N/100mm)PE Film And Nonwovens - ≥30 - 8 Bandpass Factor(m/s) ≤5.0×10-11 ≤5.0x10-12 ≤1.0×10-12 9 Hydrostatic pressure resistance 0.4MPa,1h,Not Addicted To 0.6MPa,1h,Watertight 0 . 6 M P a . 1 h , No Hysteresis 10 Water Loss(m/L) ≤18 ≤18 ≤18 11 Bentonite Durability(mL/2g) ≥20 ≥20 ≥20 Testing Program Test Methods Technical indicators coefficient of expansion ASTh D 5890 24mL/2g Fluid Loss ASTh I 5891 18mL Mass of bentonite per unit area ASTM D 5993 4.8kg/m 2 Tensile Strength ASTM D 4632 ≥400N Peel Strength ASTM D 4632 ≥65N Indicative flow rate ASTh D 5887 ≤1 ×10 -8m 3 /m 2/sec Permeability ASTMD 5887 ≤5 ×10 -9 cm/sec Tensile strength after wetting ASTh D 5321 >24kPa typical

Key words:

HAO YANG

More products