Product classification

Contact Us

If you have the intention to cooperate, please contact us immediately and we will give you feedback as soon as possible!

Three-Dimensional Composite Drainage Network

Aggregate base layer will enter the upper part of the geonet to a limited extent.

Classification:

Anti-seepage Drainage Material Series

- Description

-

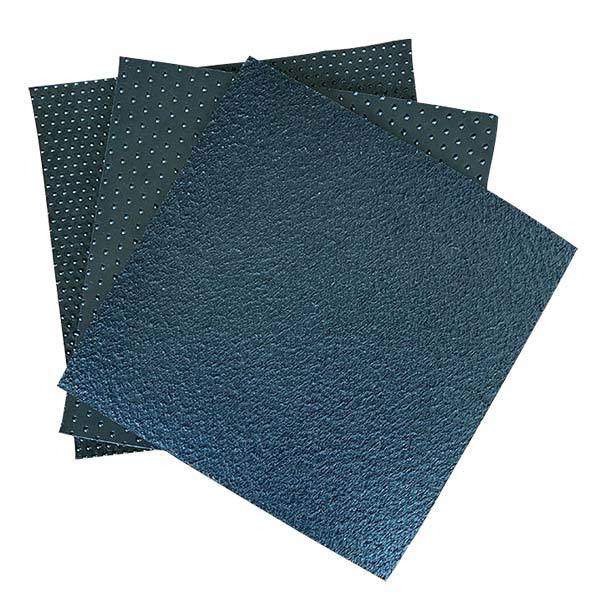

- Commodity name: Three-Dimensional Composite Drainage Network

Aggregate base layer will enter the upper part of the geonet to a limited extent.

Three-dimensional composite drainage network: composed of three-dimensional structure of plastic mesh bonded on both sides of the water-permeable geotextile, can replace the traditional sand and gravel layer, mainly used for landfills, roadbeds and tunnels, drainage of the inner wall.

Product Performance

1. Laid between the foundation and the sub-base, it is used to drain the water accumulated between the foundation and the sub-base, blocking capillary water and effectively combining it into the edge drainage system. This structure automatically shortens the drainage path of the foundation, the drainage time is greatly reduced, and can make the use of selected foundation materials to reduce the number of (i.e., can be used with more fines, lower permeability of the material), can prolong the service life of the road.

2, in the sub-base laying three-dimensional composite drainage network can prevent the sub-base fine material into the ground base (that is, play a role in isolation). Aggregate base layer will enter the upper part of the geonet to a limited extent. It also has the potential to limit the lateral movement of the aggregate subgrade, in this way acting similarly to the reinforcing effect of a geogrid. Generally speaking, the tensile strength and rigidity of three-dimensional composite drainage network is superior to many geogrids used for foundation reinforcement, and this restricting effect will improve the support capacity of the foundation.

3, road aging, crack formation, most of the rainwater will enter the section. In this case, the three-dimensional composite drainage network is laid directly under the road surface instead of the drainable foundation. The 3D composite drainage network can collect the moisture before it enters the foundation/sub-base. And a membrane can be wrapped around the bottom of the 3D composite drainage network to further prevent moisture from entering the foundation. For rigid road systems, this structure permits the design of roads with higher drainage coefficients Cd. Another advantage of this structure is that it may be possible to hydrate the concrete more uniformly (research on the extent of this advantage is ongoing). Whether for rigid or flexible road systems, this structure can extend the service life of the road.

4. In northern climates, the laying of 3D composite drainage networks can help to mitigate the effects of freezing. If the depth of freezing is very deep, the geonet can be laid in a shallower position in the sub-base as a capillary action blockage. It is also often necessary to replace the sub-base with a granular sub-base that is less susceptible to frost heave, extending down to the depth of the freeze. The frost-swellable backfill can be filled directly on top of the 3D composite drainage network up to the foundation ground line. In this case, the system can be connected to a drainage outlet so that the water table is at a depth equal to or below this depth. This potentially limits the development of ice crystals and eliminates the need to place restrictions on traffic loads during spring ice melt in cold regions.

Product Use

Mainly used in landfills, roadbeds and tunnel linings.

Product Specification

It can be produced according to different requirements of customers.

The main performance and technical index of the product

1, When the load is 720kPa and the gradient is 2%, the permeability is 2500m/d and the flow rate is 13pm/m.

2、Creep test retains more than 60% of the thickness after bearing 1200kPa load for 10000 hours.

3, three-dimensional drainage network core carbon black content of not less than 2%, density 0.94g/cm3, tensile strength of not less than 36.5kN/m, melt index 1.0 g/10min, thickness 7.6mm.

4, nonwoven geotextile apparent pore size 0.18mm, water permeability 0.26 Sec-1, permeability 0.2cm/sec, puncture strength 580N, trapezoidal tear strength 356 N, grip tensile strength 900 N, grip ductile strength 50%, burst strength 2750kPa.

Three-dimensional composite drainage network construction method

1、Adjust the orientation of the geosynthetic material so that the lengthwise direction of the material roll is perpendicular to the road.

2, The composite geodrainage network must be end-joined, with the geotextiles on adjacent geonet cores lapped along the roll of material.

3、Connect the geonet cores of adjacent geomaterial rolls with white or yellow plastic buckles or polymer straps, thus connecting the material rolls. Connect the straps at 3-foot intervals along the length of the material roll.

4.The direction of the lapped geotextile fabric should be the same as the direction in which the fill material is stacked. If the geomaterial is placed between the foundation/base and subgrade, make continuous wedge welds, flush welds, or seams to secure the top layer of the lapped geotextile. If stitching, the flat head stitch or general stitch method is recommended to achieve an affordable stitch length.

Key words:

HAO YANG

More products