Product classification

Contact Us

If you have the intention to cooperate, please contact us immediately and we will give you feedback as soon as possible!

Membrane-Covered Waterproofing Blanket

Membrane type bentonite waterproofing blanket, also known as membrane type bentonite waterproofing blanket mat, the top layer of high-density polyethylene (HDPE) film under the layer of non-woven material, impermeable sodium bentonite bottom layer of textile material.

Classification:

Waterproof Blanket Series

- Description

-

- Commodity name: Membrane-Covered Waterproofing Blanket

Membrane type bentonite waterproofing blanket, also known as membrane type bentonite waterproofing blanket mat, the top layer of high-density polyethylene (HDPE) film under the layer of non-woven material, impermeable sodium bentonite bottom layer of textile material.

Product Overview

Membrane type bentonite waterproofing blanket, also known as membrane type bentonite waterproofing blanket mat, the top layer of high-density polyethylene (HDPE) film under the layer of non-woven material, impermeable sodium bentonite bottom layer of textile material. Waterproof effect of sodium bentonite, with a special needle-punching method fixed in the high-strength geotextile between the non-woven fabric and then a layer of high-density polyethylene (HDPE) film on the adhesive layer. This product has a stronger waterproof seepage control ability than ordinary bentonite waterproof blanket. Apply to the higher requirements of waterproof seepage field such as: tunnels, subways, basements, underground passages, all kinds of underground buildings and groundwater resources rich in water projects in the seepage and leakage treatment.

Coated Bentonite Waterproof Blanket Product Characteristics

1. Green environmental protection: waterproofing blanket used in all the raw materials for the natural creation of the ground set up, do not need any additives that meet the relevant national standards, do not age, do not corrode, do not deteriorate sodium bentonite, the day, on the human body and the environment, does not produce any harm and pollution, is a natural green environmental protection materials.

2. Long-term waterproofing, excellent performance: natural sodium bentonite billions of years Gongcheng, waterproofing performance is often more durable than buildings. Sodium bentonite in the state of water pressure to form a high-density diaphragm, the thickness of 3mm when the water permeability of α × 10-11 / s below (α = 1-9), equivalent to 100 times the thickness of 30cm of clay compactness, self-preservation of water performance can be seen.

3. Simple construction: only bentonite powder and nails, washers, etc. for connection and fixing; not affected by temperature and other weather and construction environment, in the cold, humid environment can be directly constructed. Natural lap, in the lap sprinkled with bentonite powder, in contact with water bentonite waterproofing blanket that is able to lap by itself, is a kind of water to start the waterproof function of the material. After the completion of the work does not require special inspection; if found waterproofing defects easy and simple to repair.GCL in the existing waterproofing materials, the construction period is the shortest, the operation is the easiest. To shorten the construction period, cost saving effect is remarkable.

4. Self-repair ability: waterproofing materials and the integration of the object, so that sodium bentonite in contact with water, with 20-28 times the expansion capacity, even if the concrete structure vibration and settlement, GCL within the bentonite can be immediately repaired within 2mm of the cracks in the surface of the concrete, even if the diameter of the perforation as large as 30mm.

Membrane bentonite waterproofing blanket waterproofing mechanism

Sodium bentonite has a high expansion (bentonite particles can absorb water to expand their own volume of 10 ~ 30 times), when the bentonite waterproofing blanket in contact with water, in which the sodium bentonite water-absorbing expansion, in the presence of a certain extrusion pressure (from the substrate, temporary protective layer, backfill, and waterproofing blanket internal fiber tension, etc.), molecules interspersed between the arrangement of the internal gap shrinkage, the formation of dense gel structure layer, water molecules can not pass through, thus playing a waterproofing effect. Water molecules can not pass through, thus playing the role of waterproofing, its permeability coefficient of up to 5 × 10-11m/s. The greater the extrusion pressure, the higher the degree of densification, the more ideal waterproofing effect.

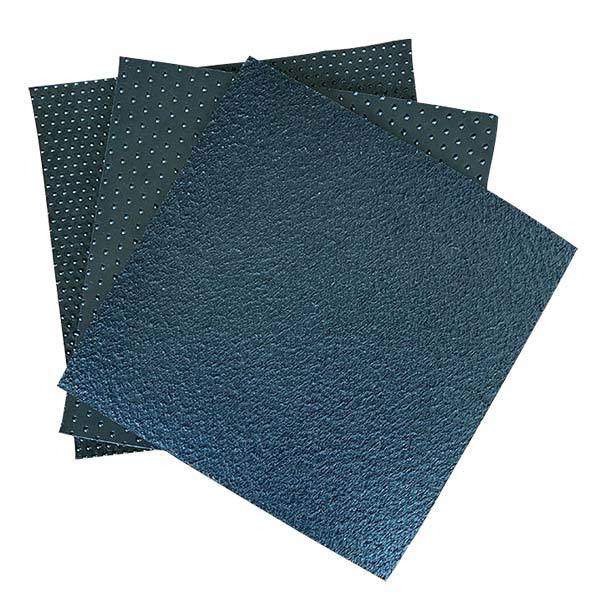

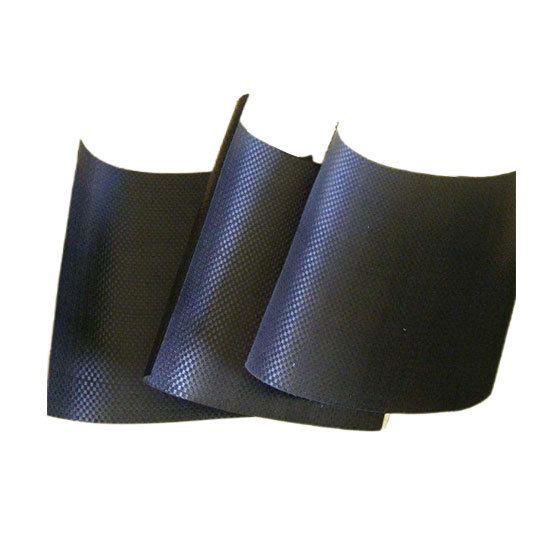

Coated Bentonite Waterproof Blanket Product Classification

Sodium bentonite waterproofing blanket finished membrane in accordance with the categories are mainly needle punched (GCL-NP/N) and membrane (GCL-OF/N) two kinds. Needle-punched type (GCLNP/N): the upper layer of non-woven geotextile, the middle layer of natural sodium bentonite, the lower layer of woven geotextile. Mainly used in ordinary, commonly used substrate waterproof seepage control treatment, such as: artificial lakes, diversion channels, irrigation channels, pools, reservoirs, dams and other water conservancy and landscape projects, as well as landfills, river training, ecological parks, wetlands, and other environmental projects overlaying type (GCL-OF/N): the upper layer of non-woven geotextile, the middle of the additional layer of natural sodium bentonite, the lower layer of spun geotextile, and finally the needle punching. After the composite process is completed, a layer of HDPE membrane is glued on the non-woven geotextile. Mainly used in underground water-rich, more stringent requirements for waterproof seepage control of underground construction and municipal transportation projects, such as: basements, subways, tunnels, underground passages, airports, railroads and municipal highways.

Coated bentonite waterproofing blanket testing indicators

Physical and technical properties Flat Indicator Bentonite content per unit area kg/m2

≥5.5

Bentonite expansion index ml/2g

≥24

Thickness mm

≥6.4

Tensile Strength N

≥600

Peel Strength N/100mm

≥65

Amount Of Blue Absorption g/100g

≥30

Permeability Coefficient m/s

≤5×10-12

Elongation %

20

Water Loss ml

≤18

Hydrostatic pressure resistance Mpa

0.6Mpa,1h watertight

Puncture Strength N

≥600

Key words:

HAO YANG

More products