Product classification

Contact Us

If you have the intention to cooperate, please contact us immediately and we will give you feedback as soon as possible!

lit. One Cloth, One Membrane

A cloth and a membrane is made of geotextiles (long and short filament needle punched geotextiles, woven geotextiles, plastic woven fabrics, etc.)

Classification:

Composite Film Series

- Description

-

- Commodity name: lit. One Cloth, One Membrane

A cloth and a membrane is made of geotextiles (long and short filament needle punched geotextiles, woven geotextiles, plastic woven fabrics, etc.)

One Fabric One Membrane Product Overview

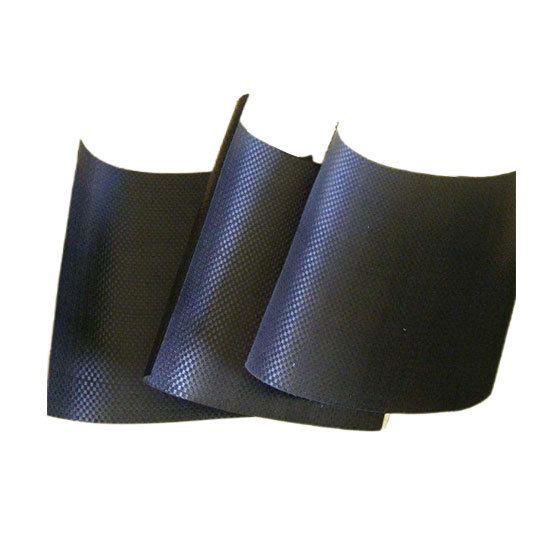

A cloth and a membrane is made of geotextiles (long and short filament needle punched geotextiles, woven geotextiles, plastic woven fabrics, etc.) and polymer materials (HDPE membrane, LDPE membrane, EVA membrane, etc.) two or more materials after calendering, hot melt composite geosynthetics.

One Fabric One Membrane Performance Characteristics

◎ Our company has accumulated experience in the production of composite geomembrane, solved the defects of similar products such as uneven length and width, uneven thickness of the film, more holes produced by the composite, etc. Each piece of product has been strictly inspected, so as to make the product maximize its role in engineering applications.

◎ Our company has now developed into a production enterprise with both calendering and thermal composite processes, and the width of the product has reached 7 meters, which reduces the seams, lowers the project cost, shortens the construction period and also reduces the hidden dangers due to the improper treatment of the seams, compared with the narrow width of the similar products.

◎ Geotextile is used instead of granular material as geomembrane protection layer to protect geomembrane impermeable layer from damage, reduce the grading requirement of bedding granularity, and act as drainage.

◎ The friction coefficient is large, can prevent the cover layer from slipping, than simple HDPE film, composite geomembrane in the nonwoven fabric has a larger friction coefficient, composite geomembrane can make the slope ratio increase to reduce the footprint.

◎ The mechanical strength of the product such as tensile, tearing, top breaking and puncture is high.

◎ There is a certain amount of deformation, the stress generated by the concave and convex defects in the sub-bedding layer is dispersed faster, and the strain capacity is stronger.

◎ The pore pressure and buoyancy force on the contact surface between the product and the soil are easy to dissipate.

◎ It has certain heat preservation effect, which reduces the damage to geomembrane caused by freezing and expansion of soil body, thus reducing the deformation of soil body.

◎ Adopting buried type laying, it has excellent anti-aging performance, which reduces the maintenance of the project.

◎ Laying construction is simple, reducing transportation, lowering the project cost and shortening the construction period.

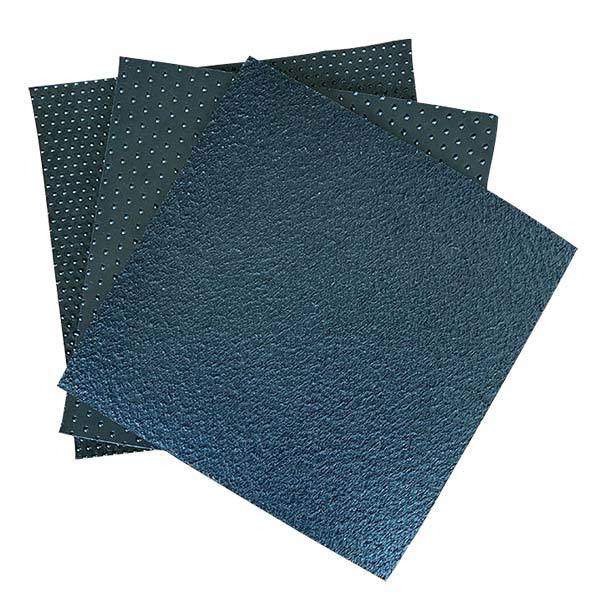

Composite Geomembrane Product Classification

One cloth and one film Base cloth: 100-1000g/m2 Film thickness: 0.2-2.0mm.

Two cloths and one film Base cloth: 80-600g/m2 Film thickness: 0.2-2.0mm.

One cloth, two films Base cloth: 100-1000g/m2 Film thickness: 0.2-0.8mm; ◎Multi-cloth, multi-layer film Base cloth: 80-600g/m2 Film thickness: 0.2-0.8mm.

Multi-Fabric Multi-Film Basecloth: 100-1000g/m2 Film Thickness: 0.2-0.8mm.

One cloth one film product specifications: width: 2-7 meters; weight: 300-2600g/m2

One Fabric One Membrane Scope of Use

One cloth one membrane because of its good plane drainage, excellent seepage control characteristics and tensile, tearing, top breaking, puncture and other mechanical strength is high, can be widely used in:

1, river embankments, lake dams, tailings dams and reservoirs, water diversion and transfer channels, liquid storage tanks (pits, mines);.

2, subway, basement and tunnel, tunnel seepage control lining.

3、Roadbed and other foundation salt seepage control.

4, embankment, dam before the horizontal seepage control cover, foundation vertical seepage control layer, construction cofferdam, waste yard.

5, seawater, freshwater farms; 6, roads, highways, railroads, waterproof layer of expansive soils and humid loess.

One cloth one membrane construction method

I. Construction Notes:

1, the use of buried type, covering thickness should not be less than 30cm.

2, the entire seepage control system should be: bedding layer, seepage control layer, transition layer, protective layer of responsibility.

3, the soil should be solid, to avoid uneven subsidence, cracks, seepage control range of turf, tree roots should be removed. The contact surface with the membrane paved with small particle size of sand or clay as a protective layer.

4, paving a cloth a membrane do not pull too tight, both ends buried in the soil part of the corrugated better, especially with rigid material anchoring, should leave a certain amount of expansion and contraction.

5, construction, should avoid stones, heavy objects directly on the composite geotechnical membrane, the best side construction, laying membrane, cover the protective layer.

II. Seams:

1. Laying:

A, sweeping composite geomembrane laying surface requires the substrate flat, no unevenness, no sharp objects, such as stones, wires, sticks, etc., for weeds should be sprayed with weed killer.

B, it is best to lay along a certain direction, and do not pull too tight, there should be a certain amount of expansion and contraction, in order to adapt to the deformation of the substrate.

C, both sides are reserved a certain width of PE film and PE film bonding layer, paving should be adjusted to each unit of composite geomembrane towards, in order to facilitate the welding of two units of composite geomembrane.

D、After laying, it should be pressed with sand bag to prevent the wind from moving and affecting the welding of the edge of composite geomembrane in the next step.

2. Welding:

A, for the paved one cloth and one film, the edge seams require that there should be no dirt, moisture, dust and so on.

B. Before welding, we should adjust the PE single film at the two edges of the seams, so that it laps a certain width and is flat and wrinkle-free.

C. When welding, the company sends technicians to be responsible for welding or technical guidance, and the welding is carried out by using the special double-track automatic crawler welding.

Mass per unit area Unit weight g/m2

400

500

600

700

800

900

1000

Note Project

Remarks

Thickness of Membrane mm 0.25~0.35 0.3~0.5

Breaking Strength KN/m

5

7.5

10.0

12.0

14.0

16.0

18.0

Vertically And Horizontally Elongation at Break % 30~100 Vertically And Horizontally

CBR Mullen Burst Strength KN≥

1.1

1.5

1.9

2.2

2.5

2.8

3.0

Tear Strength KN≥

0.15

0.25

0.32

0.4

0.48

0.56

0.62

Vertically And Horizontally Peel Strength N/cm

6

Vertically And Horizontally Vertical Permeability Coefficient cm/s

K×10-11~-13

K=1.0-9.9

Key words:

HAO YANG

More products